ICP-RIE Plasma Etching System RIE-350iPC

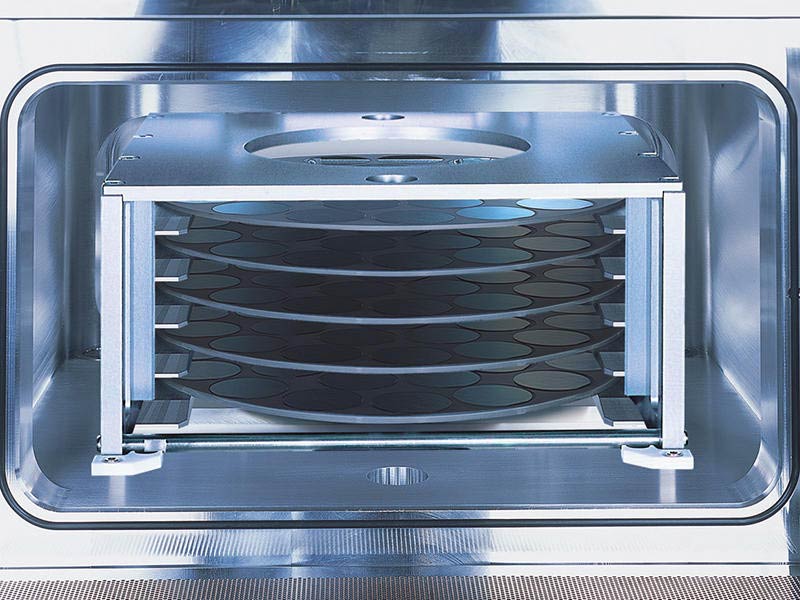

Up to ø350 mm carrier tray

Description

The RIE-350iPC is a cassette loading Inductively Coupled Plasma (ICP) etching system which handles up to ø350 mm carrier tray for multiple wafers batch processing.

This system delivers robust and reliable hardware and exceptional process control at high productivity for a wide variety of etching applications, such as power devices, microLEDs, VCSELs, LDs, capacitors, and RF filters.

Key Features and Benefits

- Processing up to ø350 mm (ø3" x 12, ø4" x 8, ø12" x 1)

- Advanced ICP Source HSTC™ (Hyper Symmetrical Tornado Coil) effectively delivers uniform high-density plasma, and excellent etch uniformity on a large area.

- A symmetrical evacuation design coupled to a TMP creates an efficient flow

- An optimized gas manifolds to deliver process gas uniformity

- Optional optical/interferometric endpoint detection system enables precise etch depth control over multiple process runs.

Applications

- High-precision etching of GaN, GaAs, InP, and SiC

- Etching of SiN and SiO2

- Etching of dielectrics and metals

- PSS (Patterned Sapphire Substrate) processing for HBLEDs