RIE Plasma Etching System RIE-10NR

Novel low-cost and high-performance

Description

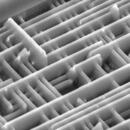

The RIE-10NR is a novel low-cost, high-performance, fully automatic reactive ion etching system which meets the most demanding process requirements for non-corrosive gas chemistry. A computerized touch screen provides a user-friendly interface for parameter control and storage. The system enables accurate sidewall profile control and high etch selectivity between materials. With its sleek, compact design, the RIE-10NR requires minimal cleanroom space.

Key Features and Benefits

- Processing up to ø220 mm (ø3” x 5, ø4” x 3, ø8” x 1)

- Highly selective anisotropic etching meets demanding process requirements

- Fully automatic “one-button” operation with full manual override

- A computerized touch screen provides a user-friendly interface for parameter control and storage

- Automatic pressure control that allows for precise control of process pressure independent of gas flow

- Dry pump and system layout allow for ease of maintenance

- The reliable and durable system with a global installed base of more than 400 systems

Applications

- Etching of various materials such as Si, SiO2, SiN, Poly-Si, GaAs, Mo, Pt, Polyimide, etc.

- Selective layer etching in failure analysis

- Photoresist ashing, stripping, and descuming

- Surface modification (wettability and adhesion improvement)

Papers

- Ashraf, M., Sundararajan, S. V., & Grenci, G. (2017). Low-power, low-pressure reactive-ion etching process for silicon etching with vertical and smooth walls for mechanobiology application. Journal of Micro/Nanolithography, MEMS, and MOEMS, 16(3), 034501.

- Hashimoto, S. (2020, July). Micro Machined Slit Between Ridge and Groove in Micro Fluid-Channel to Measure Floating Cell Deformability. In ASME 2020 Fluids Engineering Division Summer Meeting collocated with the ASME 2020 Heat Transfer Summer Conference a