Atomic Layer Deposition (ALD) Systems

Atomic layer deposition (ALD) is a thin-film growth technology that is capable of depositing pinhole-free and uniform insulator films for electronic devices (Power and RF). ALD offers exceptional conformality on the high-aspect-ratio trench and via structures, thickness control at the angstrom level, and tunable film composition based on sequential, self-limiting reactions. Samco provides a highly flexible open-loaded thermal ALD system AL-1 and loadlock plasma-enhanced ALD system AD-230LP.

-

Plasma Enhanced ALD System AD-800LP

Excellent repeatability & stability

-

Thermal ALD System AL-10

Pin-hole free films deposition

Key Features and Benefits

- Self-limiting layer-by-layer deposition

- Conformal coating on the high-aspect-ratio structures

- Pin-hole and particle free

- Wide range of precursor materials and processes

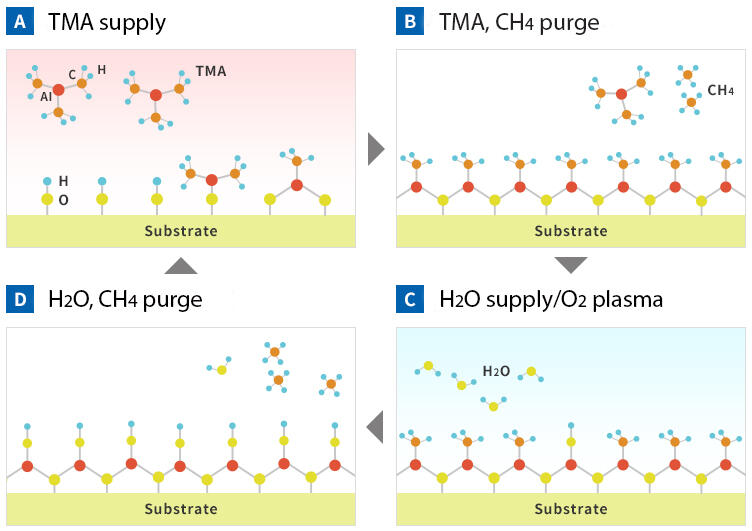

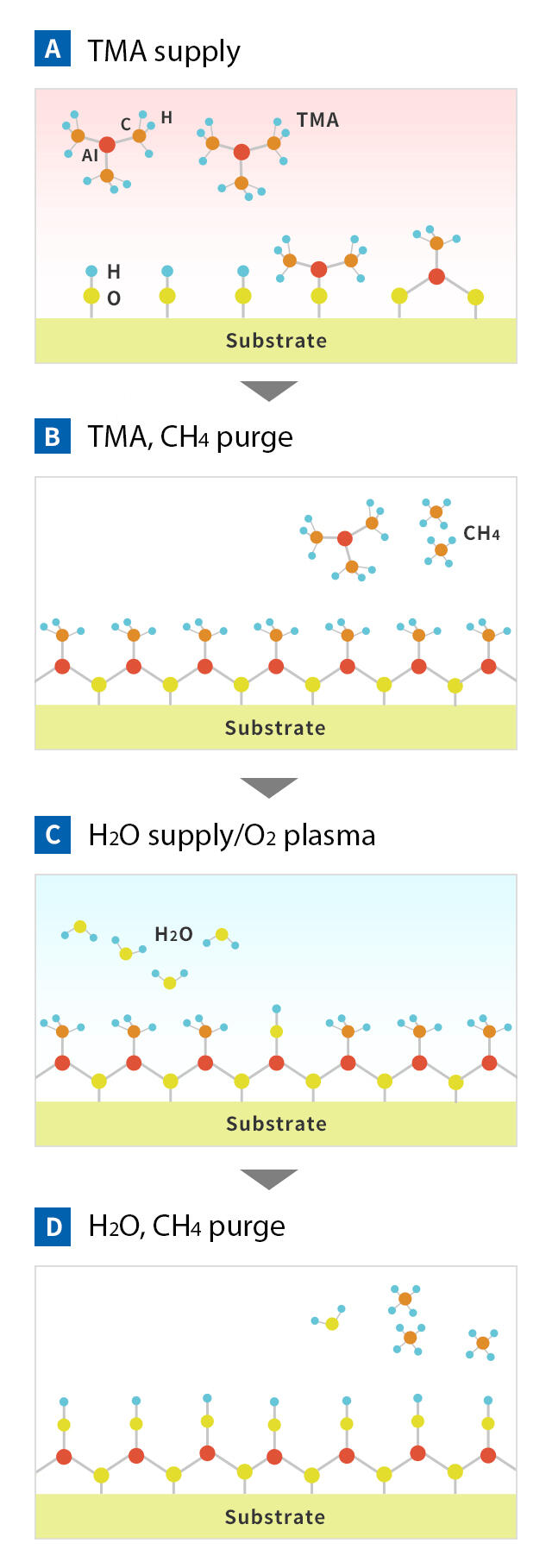

Schematic of ALD process flow

- AIOx film deposition by using TMA (trimethylaluminum) and H2O / O2 plasma.

- Repeating the cycle from A to D.

- Only one atomic layer remains on the surface of the substrate after purging in step B (self-limiting).