for Vertical Power Devices

We have been working on the development of trenching technology for GaN. It is possible to control the shape of the trench widely from vertical to forward tapered processing. We used GaN epitaxially grown on sapphire substrates and etched them with Samco's RIE-400iP.

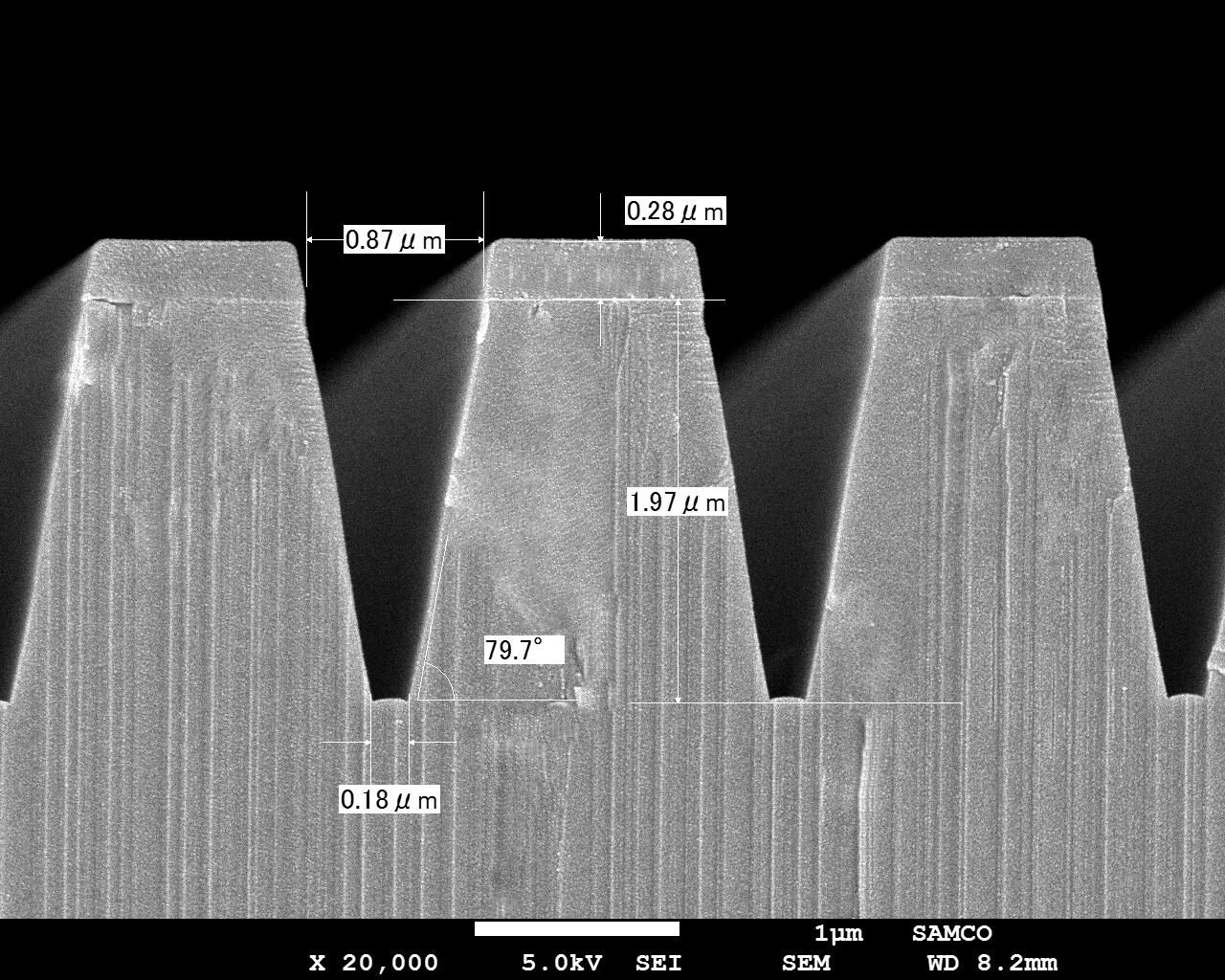

In the conventional forward taper process, particles are deposited on the side walls, which need to be removed by post-processing. With the newly developed forward tapered process, there are fewer particles on the side walls and no post-treatment is required. In addition, the new process is notable for its ability to produce a forward taper of less than 80° even in narrow patterns with etching apertures of less than 1µm. With conventional processes, the apertures are filled by sidewall deposits, which in some cases inhibit the etching process itself at narrow apertures. By controlling the RF power ratio between ICP and Bias and selecting the etching gases, we have succeeded in developing forward taper processes for GaN vertical power devices.

Tweet