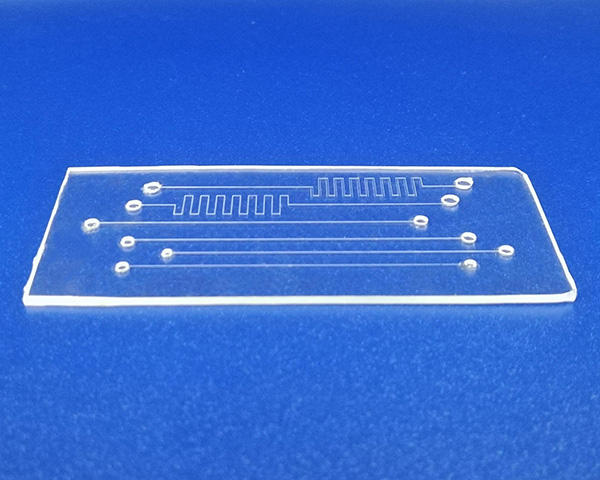

Samco plasma cleaners are suitable for plasma surface modification. Various materials such as silicon, glass, metals and polymers can be processed for wettability control. Polymethyl methacrylate (PMMA) samples were processed using a plasma cleaner and characterized with water contact angle. The samples showed hydrophilic surface after the plasma processing. This surface modification process enhances adhesion of materials, and some customers use this process for bonding of samples in microfluidic device fabrication. Typical material combination of this application is Polydimethyl siloxane (PDMS) and glass. Easy-to-use touch screen of our plasma cleaners enables one-button operation for plasma surface activation of the materials. Do you need plasma treatment of non-flat samples? We’ve got you covered! We offer plasma cleaning process solutions for inner-walls of 3D structures such as plastic and glass tubes.

Key Features and Benefits

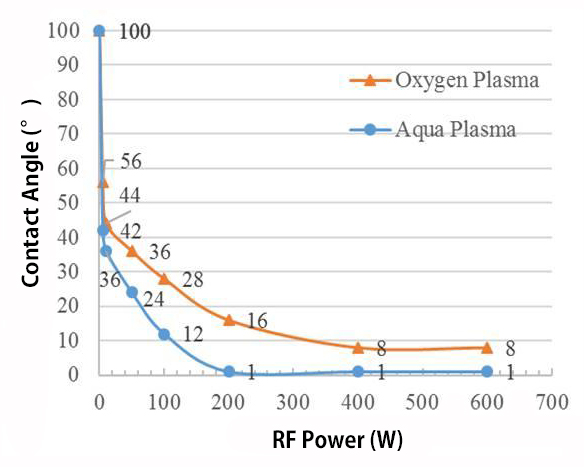

Samco H2O-based plasma cleaner offers unique process solutions of polymer/glass and polymer/polymer bonding in microfluidics fabrication. The process is specially developed by Samco and called as Aqua Plasma. Unlike VUV irradiation which is a conventional fabrication method, the Aqua Plasma process does not deteriorate auto-fluorescence of Cyclic Olefin Polymer (COP) for optical detection of molecules by fluorescence techniques. Furthermore, the plasma treatment process provides sufficient bonding strength without mechanical pressing and heating which can destroy fine micro-channel pattern.